viva: Long live, vitality

fill: Refer to the filling process and filling line

vivafill: Fill with vigor and vision. Inspired by the philosophy: less is more, we prioritize quality over quantity and focus on essentials by providing efficient and vigorous products and services.

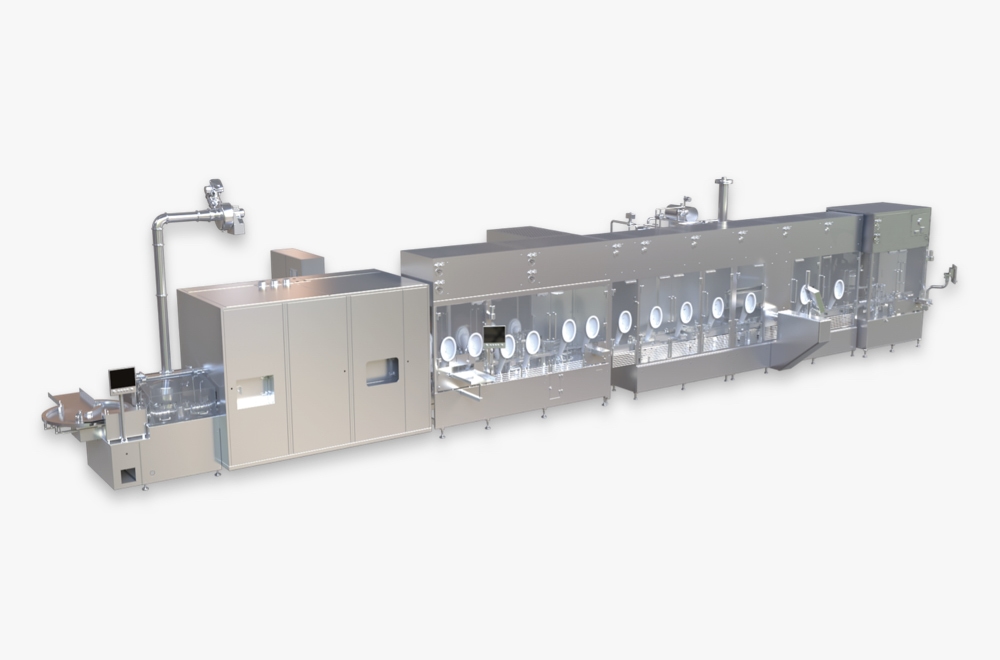

The vivafill?series consists of the latest state-of-the-art aseptic filling and closing technology to meet the requirements of the pharmaceutical industry. It is designed, developed and manufactured by AUSTAR in compliance with cGMP and meets the standards of all major regulatory bodies.

The flexibility and modularity of vivafill?series allows the customers to cope with a wide range of needs to fill both injectable liquids and powder products into diverse primary packaging forms such as glass vials, infusion bottles, pre-fillable syringes, cartridges, plastic bottles, etc. Either to be processed in bulk or as pre-sterilized (Ready-To-Use), our comprehensive range of machinery can be arranged and configured to meet the user requirements while keeping the most cost-effective and suitable solution.

The product range includes a series of washers, depyrogenation tunnels, liquid and powder filling equipment, capping machines and tray loading systems. Furthermore, it can be easily combined with LYOCORE? series for freeze drying by means of automatic loading and unloading systems to reach a maximum output of 36,000 vials per hour.

About the concern whether there is a risk to keep the Sterility Assurance of the filling and closing process, AUSTAR is offering different levels of Barrier Technology such as Opened RABs, Closed RABs and Isolators to protect the operator and/or the product that can be seam-less integrated with vivafill?series. Whatever the fundamental base of your Risk Assessment, we at AUSTAR might help your organization to mitigate any potential risk.

Whether you are a C(D)MO, a research laboratory, a pharmaceutical or biopharmaceutical company, we at AUSTAR shall support you throughout the entire life cycle of our machines. Rely on our global net of experts to discuss the specifics of your project and together will lead the future of the pharmaceutical industry.

Search

Search 中文

中文